Over the past few years, humanoids have become the talk of the internet, thanks to breakthroughs in artificial intelligence (AI), machine learning (ML), synthetic data and robotics. Companies worldwide are racing to deploy intelligent, autonomous humanoids that can work alongside humans in industrial environments.

As seen in recent collaborations between major AI and robotics firms, such as Apptronik, Google DeepMind, NVIDIA and Foxconn, companies strive to create versatile robots capable of dynamic, real-world tasks.

With an increasing focus on efficiency, safety, and automation, humanoids are poised to become an essential part of the workforce. Companies like FigureAI, Tesla, UBTECH, Agility Robotics, and Addverb are now exploring humanoids.

In an interview with AIM, Satish Shukla, co-founder of Addverb, discussed the company’s plans to launch its humanoid this year and his views on the future of humanoids.

Shukla believes it will take another three to four years for humanoids to become as prevalent as humans. “For every human, we probably might have one humanoid,” he said.

Addverb focuses on AI, computer vision, and gesture-based control to expand its portfolio of autonomous and semi-autonomous robotic solutions. The company also claims to address industrial bottlenecks in warehouse operations, e-commerce logistics, and security automation.

Humanoids to Enter Soon

As per Shukla, Addverb aims to launch its first humanoid robot in Q4 (October to December) of 2025. Unlike traditional robotic automation, humanoid robots offer the advantage of seamless integration into human-centric environments without requiring major infrastructure changes.

“We don’t see it as a consumer product per se, but it could find application in…a burger joint, but not for a personal user or consumer-based,” Shukla added.

The robot could function in workplaces such as warehouses, healthcare facilities, and security operations, where automation has yet to fully replace manual processes. He also noted that while humanoid robotics is advancing, widespread adoption will take time.

These robots will evolve through iterative upgrades, ensuring robustness and adaptability for various industries. The company is leveraging its partnerships with Reliance and other innovation-focused firms to refine and test its humanoid solutions before a large-scale rollout.

In November last year, Addverb’s co-founder and CEO, Sangeet Kumar, said that the company would initially unveil 100 robots in 2025, which would be used across various industries, including energy and retail.

He noted that the humanoids are advancing at a pace comparable to those in the US, China, and Europe in terms of speed, height, and dexterity. The focus is on commercialising military-grade robots and exploring their deployment on Mars.

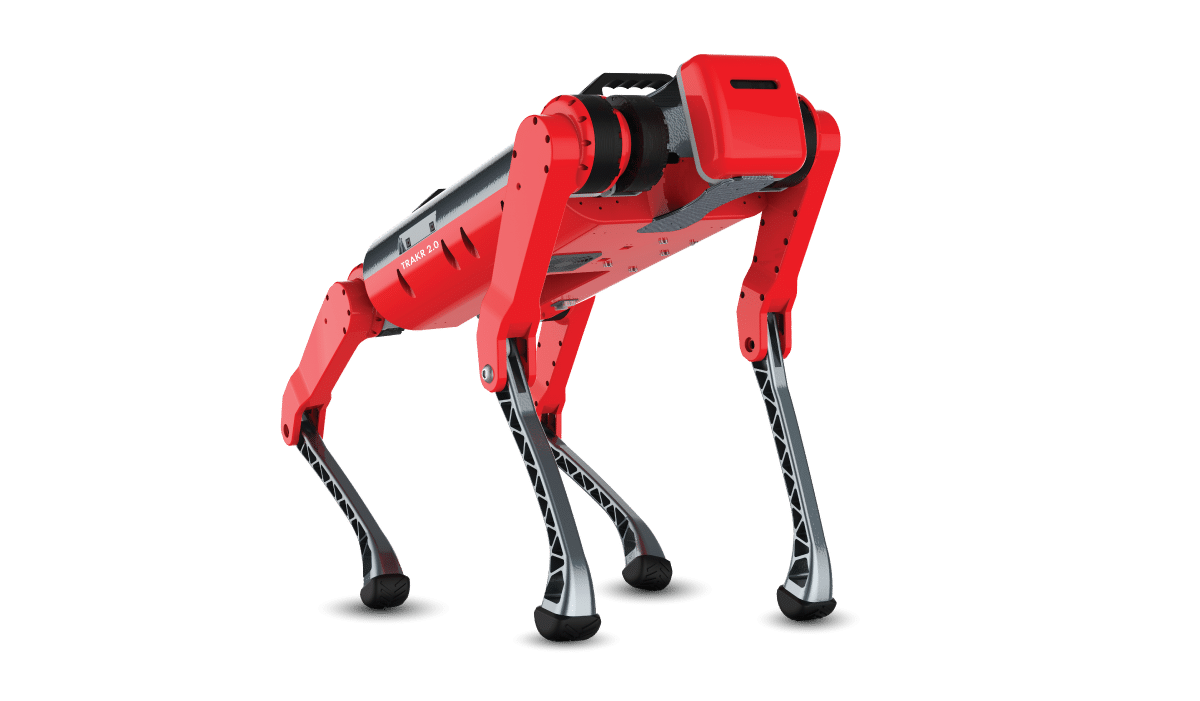

Trakr 2.0 Advances Quadruped Robotics

Trakr 2.0, to be launched at LogiMAT India 2025, is an upgraded version of Addverb’s quadruped robot designed for industrial, security, and healthcare applications. It features a payload capacity of 20 kg, a 90-minute battery life, and stereo cameras for improved autonomous navigation.

Unlike conventional wheeled robots, Trakr 2.0 operates on four legs, allowing it to traverse complex industrial terrains. It takes the company from “wheeled robotics to legged robotics”, according to Shukla. The robot is intended for warehouse automation, security patrolling, and disaster management applications.

Addverb previously introduced quadruped robots for warehouse coordination, but Trakr 2.0 expands its use cases to healthcare logistics, surveillance, and industrial maintenance.

“There will be a fleet of quadrupeds that will display agility, coordination, better planning, efficiency and overall collective intelligence of how a group of quadruped can perform different tasks,” Shukla said.

The robot’s integration with AI-based perception systems positions it as a potential alternative to traditional security and monitoring solutions. The stereo cameras enhance vision-based navigation, allowing the robot to function in low-light and dynamic environments.

Shukla expressed that the robotics and automation industry requires a specialised skill set, but the availability of trained professionals remains limited. Addverb acknowledges this gap and focuses on hiring young engineers willing to learn and experiment. Addverb has a global workforce, with professionals from over 60 nationalities contributing to product development. The company runs internal upskilling programs to prepare training graduates from campuses.

Warehouse Automation Gets Smarter with Gesture-Based Picking

Syncro is Addverb’s collaborative robot designed to automate picking operations with AI-driven precision. It enhances efficiency by executing pick-and-place tasks with minimal manual intervention.

With a payload capacity of up to 10 kg, an extended reach of 1,300 mm, and a speed of 1 m/s, Syncro ensures faster order fulfilment while maintaining 99.9% picking accuracy.

The robotic picking arm grips and lifts items from storage containers with precision. Customisable end-of-arm tooling and multi-axis movement make it adaptable for handling various stock-keeping units (SKUs). Syncro also facilitates decanting by efficiently transferring items from source bins to destination bins, optimising warehouse automation.

Another innovation, HOCA (high-order carousel automation), is an advanced batch-picking system designed for warehouses that require high-volume, space-efficient automation.

The system can handle payloads of up to 54 tons while operating within a compact picking zone of 5–10 square metres.

Its design enables automated goods retrieval, eliminating the need for manual aisle navigation. The system claims to ensure an accuracy rate exceeding 99%, reducing errors in inventory management and optimising order fulfilment workflows.

According to Shukla, HOCA is built for e-commerce fulfilment centres, dark stores, and large-scale industrial storage. The batch-picking feature allows multiple orders to be processed simultaneously, a function aimed at businesses experiencing seasonal demand spikes.

Moreover, Brisk, another launch by the company, introduces gesture-recognition technology into warehouse operations, allowing workers to execute tasks with minimal manual effort. The system incorporates a glove-based EAN reader that facilitates barcode scanning, accelerating the order processing cycle.

Designed to reduce non-value-adding movements, Brisk replaces traditional walking-and-picking workflows with an automated goods-to-person system.

The interface adapts to varied lighting conditions, ensuring smooth operation in low-visibility warehouse environments.

Brisk builds on Addverb’s existing work in computer vision, reinforcement learning, and AI-driven automation. The product will target e-commerce, large-scale retail warehouses, and manufacturing hubs where manual picking inefficiencies impact productivity.

Why Reliance?

Reliance is a strategic investor in Addverb, which provides a platform for developing and testing automation solutions across multiple industries. With business verticals spanning petrochemicals, retail, digital services, fashion, e-commerce, and new energy, Reliance offers a broad environment for deploying robotics and automation technologies.

As Shukla explained, Addverb has worked on several key projects within Reliance, including a remote ultrasound solution, a 5G-enabled robot for the Jamnagar Refinery, and automation for returns handling in retail, grocery, and fashion operations.

This partnership enables Addverb to scale its solutions rapidly, allowing for real-world testing in a collaborative environment.

Implementing automation at Reliance’s operational scale gives the company a controlled environment to refine its products before expanding globally. The relationship also accelerates product development and market entry, helping Addverb bring innovations to market faster.

While Reliance plays a crucial role in infrastructure and deployment, Addverb is also working with Intel, NVIDIA, and Siemens to develop robotics and automation solutions.

While Addverb competes with major industrial robotics firms, including ABB, which focuses on industrial robotic arms, mobile robots, and cobots, competitors rely heavily on simulation and synthetic data for robot path planning.

Addverb takes a different approach by controlling the entire end-to-end supply chain, from conceptualisation to deployment. The company has dedicated in-house teams for research and development, embedded systems, electrical engineering, manufacturing, and software development.

This structure allows Addverb to reduce hardware complexity, cost, and weight. The ability to implement over-the-air (OTA) updates ensures continuous improvement post-deployment.

Addverb has also developed custom controllers, enabling better optimisation of robotic functions. With over 350 customers and its own manufacturing facility, the company generates large-scale real-world data to refine automation systems.